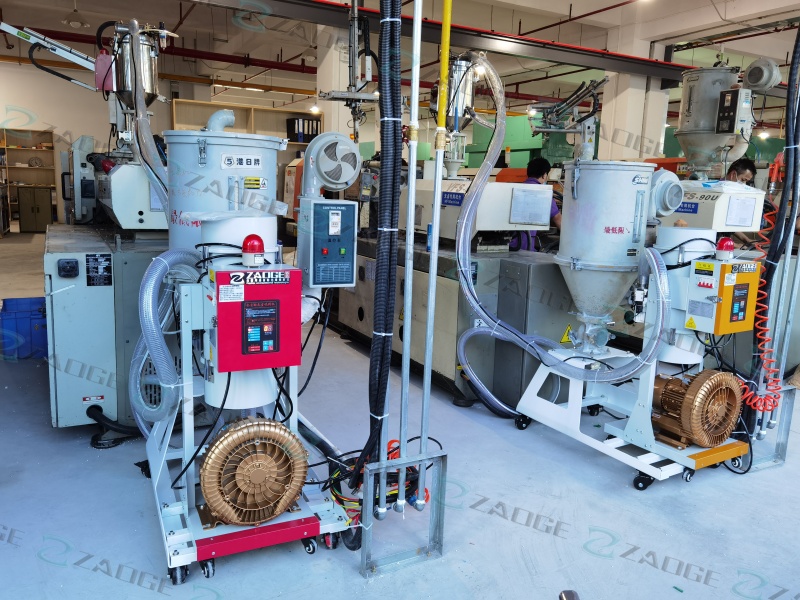

In modern production workshops, flexible equipment layout is becoming crucial for improving efficiency. Traditional large-scale feeding systems often lock production lines into fixed positions, requiring significant effort for each adjustment. The ZAOGE vacuum feeder, with its innovative design, changes this situation.

The most notable features of this vacuum feeder are its compact size and exceptional mobility. Universal industrial wheels on the bottom allow operators to easily maneuver it to any desired location. The included wired controller makes operation easy and convenient. Operators can start, stop, and adjust the speed from several meters away, eliminating the need for back-and-forth.

Particularly noteworthy is its motor startup protection feature, which effectively mitigates voltage fluctuations, prevents current surges during startup, and significantly extends equipment life.

In terms of maintenance, the ZAOGE vacuum feeder demonstrates a forward-thinking design. The carbon brush wear warning function proactively alerts operators before replacement is required, preventing unexpected downtime due to brush depletion. The operating time recording function helps managers accurately monitor equipment usage, providing a reliable basis for preventative maintenance.

The ZAOGE suction machine is not only a piece of equipment, but also a powerful assistant for improving workshop production efficiency. Its appearance makes flexible adjustment of production lines possible, injecting new vitality into the sustainable development of enterprises.

———————————————————————————–

ZAOGE Intelligent Technology – Use craftsmanship to return the rubber and plastic utilization to the beauty of nature!

Main products: environmentally friendly material saving machine, plastic crusher, plastic granulator, auxiliary equipment, non-standard customization and other rubber and plastic environmental protection utilization systems

Post time: Oct-30-2025