● Automatic customization of sprues

Heat recycling of sprues, crushing, conveying, sieving, mixing with new materials, and rod molding.

● Automatic customization of defective products

Undesirable products are fed into a conveyor belt, conveyed, sifted, bagged, weighed, and recycled.

● Customized copper-plastic separation system

Waste wire a conveyor belt input a crushing a conveyor a screening separation a vibrating filtration a pure rubber skin a collection a bagging a high efficiency use.

● Immediate crushing and bagging customization

Undesirable products are put into crushing, conveying, sieving, and bagging.

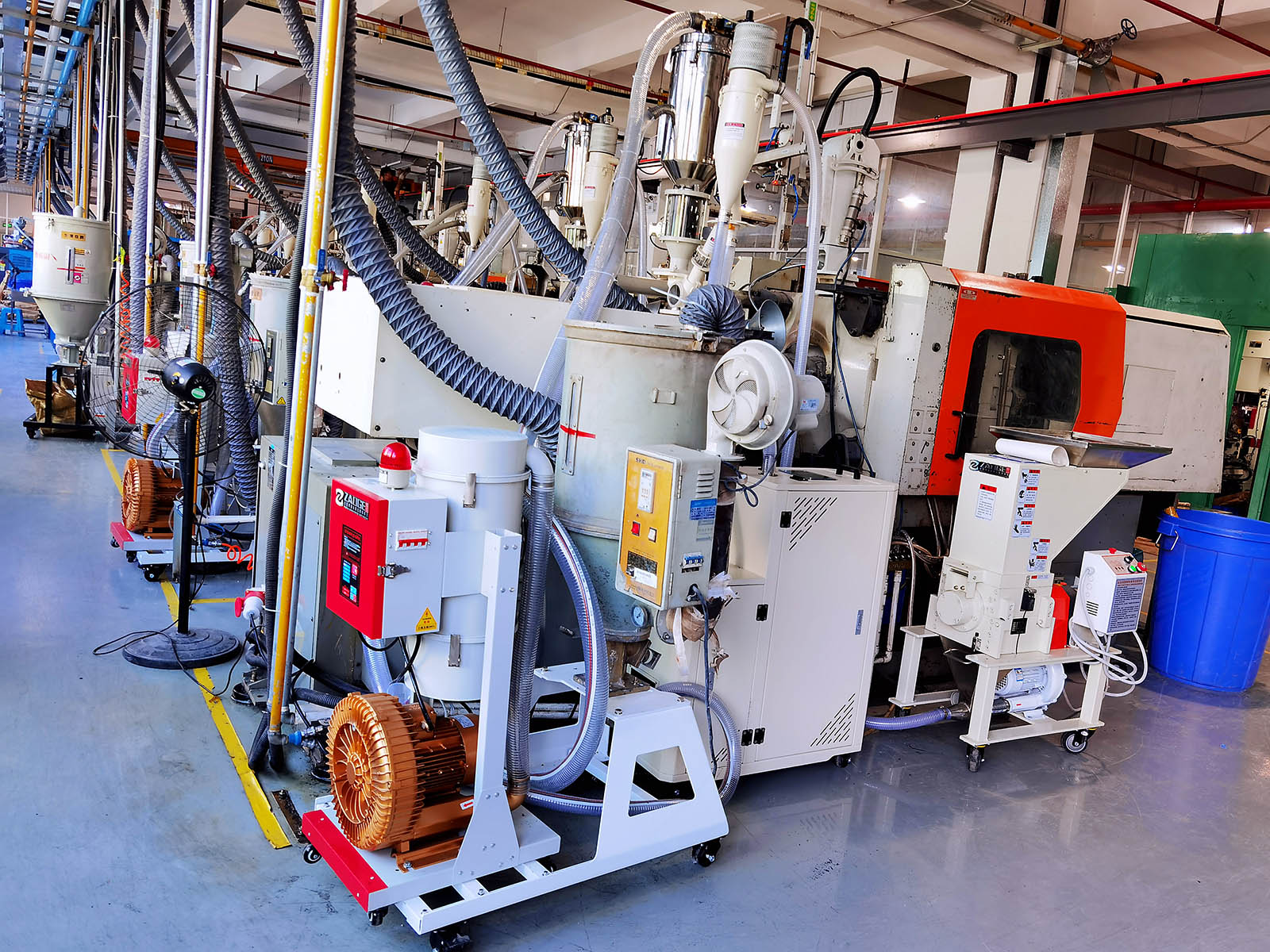

● Feed system customization

Plastic material one dehumidification, one thousand drying, one conveying, one weighing and measuring, one automatic mixing, one screw molding.

● System

Material-saving integrated design, fully automatic completion.

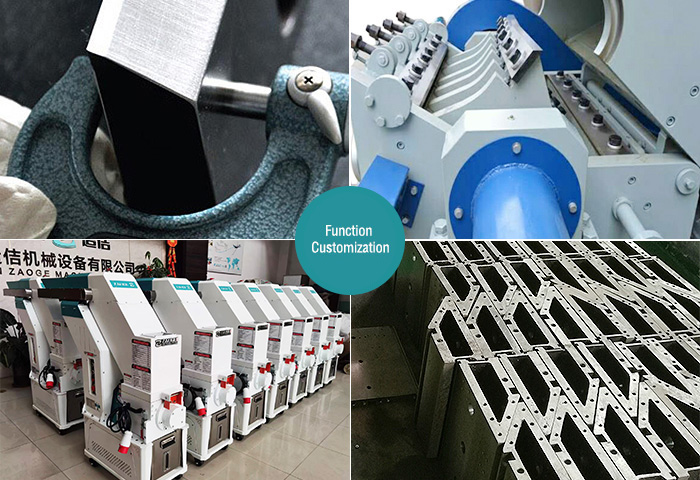

● Structure

Different knife structure for different plastic materials.

● Performance

Conveying effect, separation and screening, particle size, noise requirements, automatic bagging, can be flexibly designed and combined.

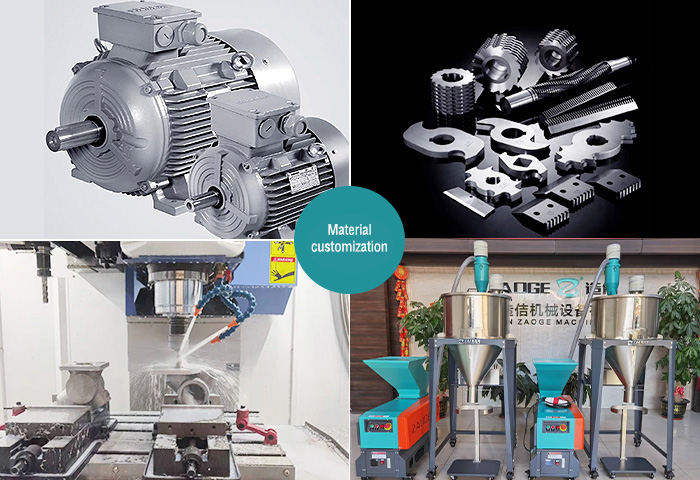

● Transmission customization: Mitsubishi, YASKAWA, Siemens, TECO, Tatung, Dongguan motor, etc.

● Knife material customization: imported TM4, DC53, SKD11, TKD, etc.

● Powder sieving customization: stainless steel cyclone device, environmental protection dust filter and collection box.

● Customized mixing ratio: 25#aluminum+golden sand.

● Customized conveying pipe: environmental protection PVC pipe, 304 stainless steel pipe, etc.

● Fasteners: galvanized, 304 stainless steel, etc.

● Sheet metal customization: cast iron, A3 plate, stainless steel, etc.

● Processing technology: Cavity process requires CNC processing to ensure the accuracy of each accessory up to +0.05mm.

● Rack process: According to the technical drawings, require all the laser down to the exact size, error control in +0.2mm.

● Welding process: grinding off burrs and cutting slag, grinding and leveling the parts to be welded before welding, grinding and polishing again. The welding point should be fish scale shape, and the polishing point should be curved or brushed.

● Assembly process: determine the sequence of steps flow chart before installation, all components are installed horizontally, all 304 fasteners are equipped with non-slip nuts, bullet spacers, downward installation, to ensure that all structural clearance and firmness.

● Testing process: Before test run, the machine should be qualified in each parameter, strictly check the assembly parameter standard of tool, transmission and screen parts, and then test the machine for 24 hours to make sure it is normal before packing for shipment.

● Thickness of cast steel parts customized

30~150MM, +0.1mm to ensure stability, sealing and sound insulation

● Knife hardness customization

After high temperature 1230-1300°C heat treatment and -190 degrees cold treatment, the knife reaches 55 degrees ~ 65 degrees, +0.2 degrees. Ensure strength, hardness, corrosion resistance, toughness, etc.

● Plate thickness customization

1.5~20MM, +0.05mm to ensure stability, sealing and sound insulation.

● Machine Size Customization

Different models of chassis size within a reasonable range can be customized according to the customer, size error control in 5mm.

● Sieving device customization

For height restriction, it can be customized according to customers' requirements.

● Granule size customization

According to different customers' requirements, we can customize the screen size for you.

● Customized storage and bagging

The capacity can be customized according to the needs.

● Color customization

The color of our machine adopts light green as the main tone and grey as the auxiliary tone, and we can also make the color according to the customer's requirements.

● Logo customization

Our company's logo and pattern will be printed on the machine. Of course, we can also customize personalized patterns according to customer requirements.

● Placement customization

Different size, environment, design different equipment size.

● Feeding method customization

Different directions and shapes can be chosen for the feeding method.

● High-end soundproof customization

All soundproof cotton and board design, reduce the noise by 40~60db.

● Operation mode customization

PLC or remote or control box.

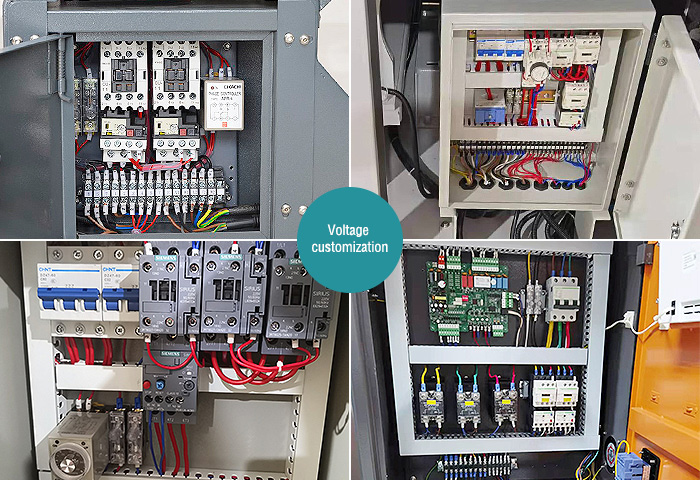

● The equipment meets the standard voltage of daily electricity in China

1PH-220V-50Hz, 3PH-380V-50Hz.

● Can be customized according to customer demand for non-standard state voltage under the use of the region

1PH-220V, 3PH-220V, 380V 50Hz/60Hz, 3PH-380V, 415V-50Hz/60Hz (3PH200V/220V 50H/60Hz), etc. can be customized to meet your non-standard voltage.

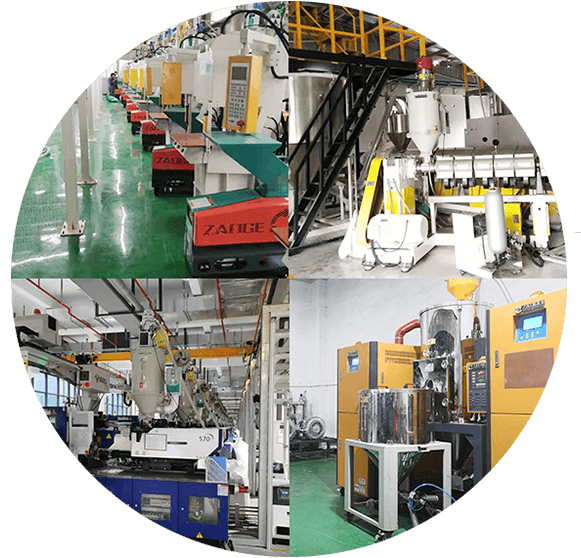

Why Choose ZAOGE?

Non-standard customized rubber and plastic environmental protection utilization system why choose ZAOGE?

● Sales totalization system design

Semi-automatic/full-automatic integrated system design for new and used plastic materials.

● Provide plastic environmental protection utilization program

Sprues clean, dust removal, heat recovery and use within 30 seconds

● Zero after-sales service cost

Started from Yan Zhi, established in quality, trouble-free use of 5 ~ 10 years

● Focused on rubber and plastic utilization for 46 years

Sold 117,000 units worldwide.

Customers Verification

Verification of the creation of letters witnessed by many customers Durable

more than 50% compared to the same period, saving effort and money.

Silent Plastic Crusher

Low Speed Plastic Crusher

SLow Speed Plastic Shredder

plastic recycling Crusher

Powerful plastic Shredder

Plastic Soundproof Crusher

Customization Process

Sourcing good machinery is easy in 4 simple steps

01

Preliminary Inquiry

"Call us or come to our factory for a consultation Detailed requirements"

02

Determine the type of machine

"Determine whether standard or customized Confirm specific parameters and quotation"

03

Signing Contracts

"Signing the transaction contract Clarify the work of both parties"

04

Delivery and Installation

"Installation and commissioning by professional personnel online guidance"