Low-Speed Plastic Recycling Shredder

Description

The Low-Speed Plastic Recycling Shredder is suitable for grinding tough sprue materials such as PP, PE, and nylon, etc. For example, sprue materials generated from injection molding in industries such as spray pumps, cosmetics, toys, and home appliances.

The Low-speed Plastic Recycling Shredder adopts a stepped V-shaped knife structure, which ensures smoother feeding and more stable operation. It employs a joint venture motor to reduce power consumption, prolong lifespan, and ensure stable and safe operation. The control system guarantees the safety of the machine during use.

Description

The Low-speed Plastic Recycling Shredder is suitable for grinding tough sprue materials such as PP, PE, nylon, etc. For example, sprue materials are generated from injection molding in industries such as spray pumps, cosmetics, toys, and home appliances.

The Low-speed Plastic Recycling Shredder adopts a stepped V-shaped knife structure, which ensures smoother feeding and more stable operation. It employs a joint venture motor to reduce power consumption, prolong lifespan, and ensure stable and safe operation. The control system guarantees the safety of the machine during use.

More Details

Crushing Chamber

This product features an open structure design and is made of 25mm thick steel plate, which has been precisely processed with CNC technology. It is easy and fast to replace the color and material.

Unique Cutting Tools

Stepped rotary blades arranged in a V-shape can grab the material to be crushed in the center of the crushing chamber, while also increasing the wear resistance of the crushing chamber sidewalls when processing fiber products and glass reinforced plastics. In addition, the design of the stepped rotor blades ensures that only one blade is cutting at any time, thereby increasing the cutting torque.

Blade Material

The blades are made of Japanese NACHI material, known for its hardness and wear resistance. The V-shaped design of the blades ensures quieter cutting and less generation of powder.

Power System

This product is manufactured by Siemens or JMC, and it features stable operation, improved performance, greater torque, lower power consumption, and high safety.

Control System

This product, manufactured by Siemens or Schneider Electric, stands out for its heightened stability and safety features, ensuring better protection for equipment and operators.

Control System

This product, manufactured by Siemens or Schneider Electric, stands out for its heightened stability and safety features, ensuring better protection for equipment and operators.

Plastic Recycling Shredder Applications

Automotive Parts Injection Molding

Cosmetic Bottleswatering Cansplastic Condiment Bottles

Fitness And Medical Molding

Household Electrical Appliances

Injection Molded Toys

Medical Injection Molded Products

Pump Dispenser

Stationery Blow Molding

Specifications

|

ZGS5 series |

||||

|

Mode |

ZGS-518 |

ZGS-528 |

ZGS-538 |

ZGS-548 |

|

Motor Power |

2.2KW |

3KW |

4KW |

4KW |

|

Raotating Speed |

150rpm |

150rpm |

150rpm |

150rpm |

|

Rotating blades |

12PCS |

18PCS |

30PCS |

45PCS |

|

Fixed blades |

2(4)PCS |

2(4)PCS |

2(4)PCS |

2(4)PCS |

|

Rotary working width |

120mm |

180mm |

300mm |

430mm |

|

Cutting Chamber |

270*120mm |

270*180mm |

270*300mm |

270*430mm |

|

Screen |

6MM |

6MM |

6MM |

6MM |

|

Weight |

150Kg |

180Kg |

220Kg |

260Kg |

|

Dimensions L*W*H mm |

830*500*1210 |

860*500*1210 |

950*500*1210 |

1200*500*1360 |

|

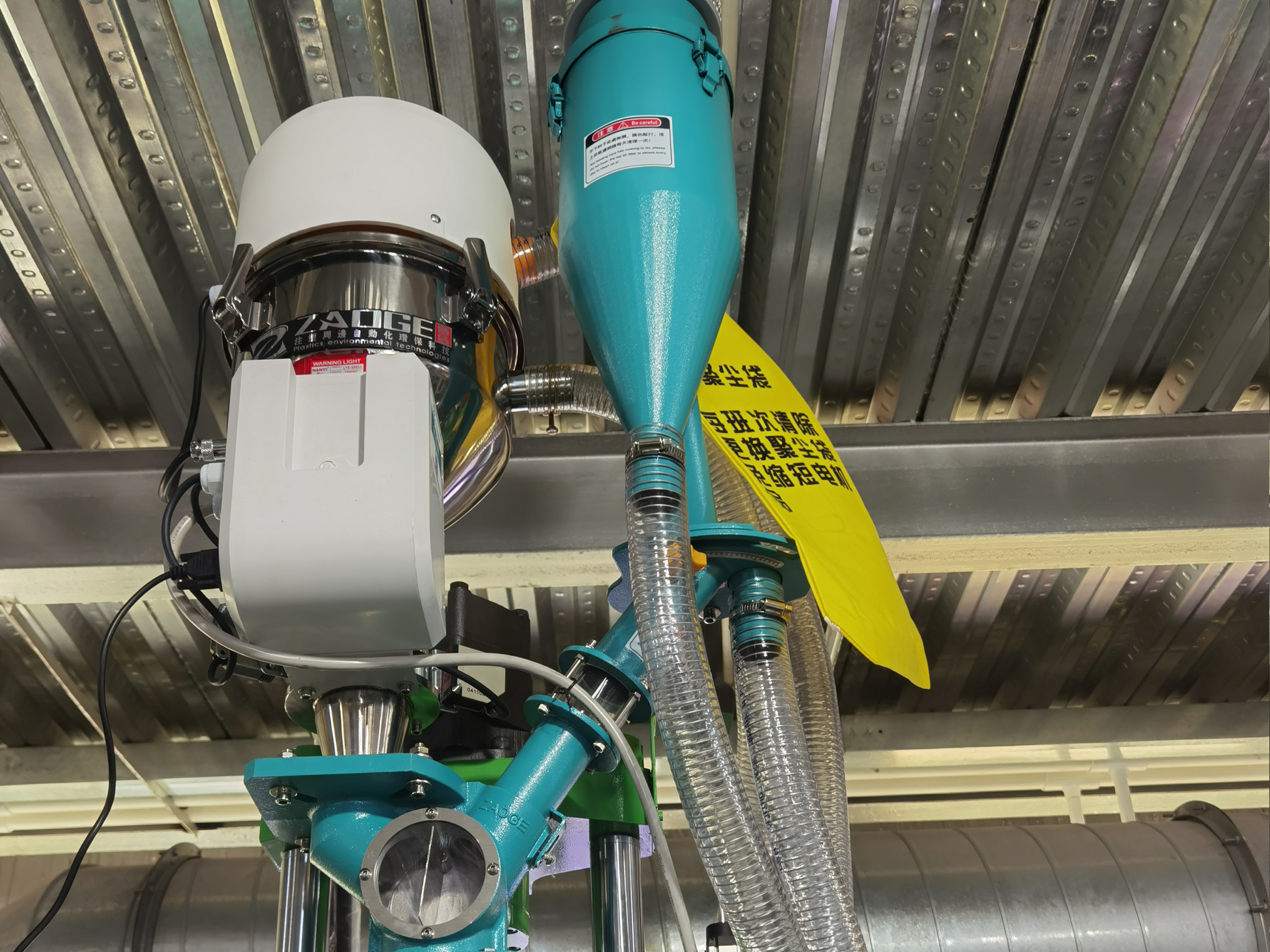

Optional parts |

400W Conveyor fan,Sieve Powder Cyclone Separator,Electrostatic output tube,Proportional smooth tube,Three fork mixed packing seat. |

|||