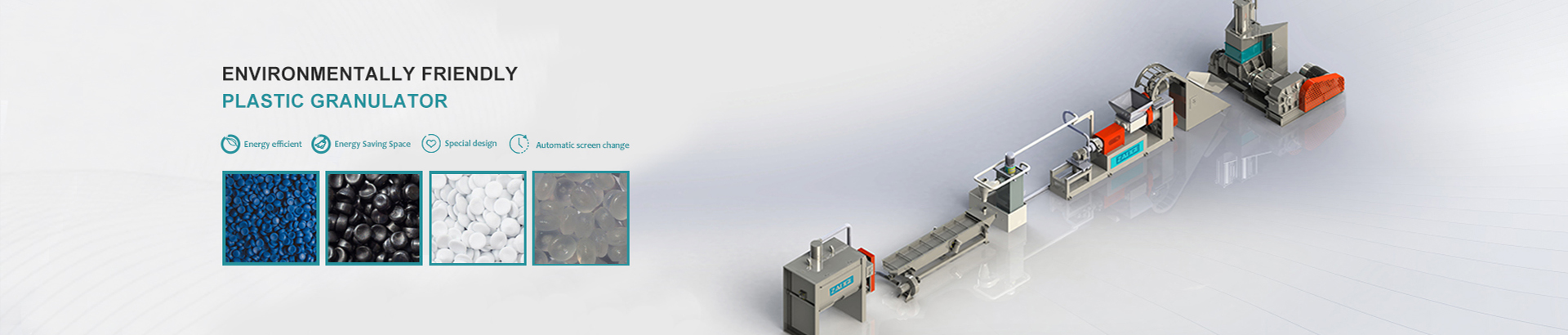

Plastic Granulators

Double Wrist Plastic Granulator

● Power transmission system: Adopts high-torque gearbox, which is energy-saving when the motor outputs power.

● Dedicated screw material tube design: According to the characteristics of recycled materials, a dedicated screw is designed to ensure that it can fully remove water and impurities such as waste gas.

● The extruder is equipped with a pressure sensing device: When the pressure is too high, the warning light or buzzer will notify the need to replace the filter screen.

● Applicable materials: Recyclable plastics such as TPU, EVA, PVC, HDPE, LDPE, LLDPE, HIPS, PS, ABS, PC, PMMA, etc.

Three-In-One Plastic Granulators

● High torque gearbox: More power saving when motor output. Gear box is precision ground gears, low noise, smooth operation

● screw and barrel are made of imported materials:Good wear resistance and long service life

● mold head cutting pellet: The labor cost of manual pulling can be eliminated.

● Extruder with pressure-sensitive side gauge: When the pressure is too high, the warning light or the buzzer will notify to replace the filter screen

● Single extrusion model: Suitable for granulation of clean raw materials, such as leftovers and leftovers of cut film

● Applicable materials: PP, OPP, BOPP, HDPE, LDPE, LLDPE, ABS, HIPS and other recycled plastics