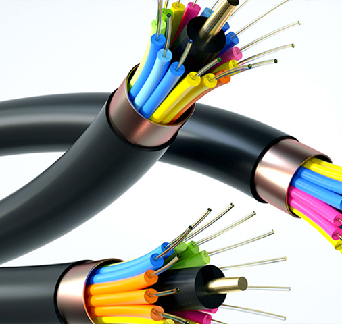

Commonly used cable insulation materials include polyethylene (PE), cross-linked polyethylene (XLPE), polyvinyl chloride (PVC), halogen-free materials, etc. They can provide the insulation properties required by cables.

1. Cross-linked polyethylene (XLPE): Cross-linked polyethylene is a thermoplastic that converts linear polyethylene chains into a three-dimensional network structure through chemical cross-linking. It has excellent electrical insulation properties, heat resistance and chemical corrosion resistance. In the cable industry, cross-linked polyethylene is widely used as an insulation material because it has high heat resistance and can withstand high temperatures without releasing harmful gases like PVC.

2. Polyvinyl chloride (PVC): Polyvinyl chloride is a widely used plastic material that has become one of the main insulation materials in the cable industry due to its excellent electrical properties, low cost and easy processing. PVC has good heat resistance, flame retardancy and corrosion resistance, and is easy to dye and process. However, harmful gases will be released at high temperatures, so special attention should be paid when used in high temperature environments.

3. Polyethylene (PE): Polyethylene is a widely used plastic material that is widely used in the cable industry due to its good flexibility, impact resistance and electrical properties. PE material has excellent low temperature resistance and chemical corrosion resistance, and is easy to process and dye. However, its heat resistance is poor, so you need to pay attention to the temperature limit when using it.

4. Low smoke halogen-free material: Low smoke halogen-free cable is a cable made using special materials and processes to reduce the smoke and toxic gases released during fire. The insulation and sheath materials of this cable do not contain harmful substances such as halogens, so no toxic and corrosive gases will be released during combustion. Low smoke halogen-free cables are widely used in places where flame retardancy and low smoke requirements are required, such as buildings, ships and trains.

Application scope:

1. Cross-linked polyethylene (XLPE): widely used in wires and cables, pipes, plates, profiles, injection molded parts and other fields. It can be used to manufacture automotive wiring, home appliance wiring, audio wires, high-temperature cables, aviation wires and other demanding products. High quality cable products.

2. Polyvinyl chloride (PVC): It is widely used in building materials, industrial products, daily necessities, floor leather, pipes, wires and cables, packaging films, etc.

3. Polyethylene (PE): Due to its excellent properties, it has been widely used in many fields, including agricultural films, wires and cables, pipes, medical materials, etc.

4. Low-smoke halogen-free cables: suitable for high-rise residential buildings, public places and other places with strict environmental hygiene requirements, and can also be used in cable systems in important places such as subway stations and nuclear power plants.

Cable extruders in cable factories generate hot startup waste every day. So how should we effectively deal with these startup wastes? Leave it to ZAOGE unique recycling solution. ZAOGE plastic crusher online instant crushing, instant use of hot waste generated by cable extruders, crushed materials are uniform, clean, dust-free, pollution-free, high quality, mixed with raw materials to produce products of high quality.

Post time: Jun-05-2024