1. Injection molding principle

Add granular or powdered plastic to the hopper of the injection machine, where the plastic is heated and melted to maintain a flowing state. Then, under a certain pressure, it is injected into a closed mold. After cooling and shaping, the melted plastic solidifies into the desired plastic part.

2. Characteristics of injection molding

The production cycle of injection molding is short and the productivity is high. Using injection molding can produce plastic parts with complex shapes, high size requirements, and various inserts, which is difficult to achieve by other plastic molding methods; Secondly, injection molding is easy to achieve automation in the production process, such as injection, demolding, gate cutting, and other operational processes. Therefore, injection molding has been widely used.

2.1 Advantages:

Short molding cycle, high production efficiency, easy to achieve automation, capable of forming plastic parts with complex shapes, precise dimensions, metal or non-metal inserts, stable product quality, and wide adaptability

2.2 Disadvantages:

The price of injection molding equipment is relatively high; The structure of injection molds is complex; High production costs, long production cycles, and unsuitable for the production of single and small batch plastic parts.

3. Application

Except for a few thermoplastic materials (fluoroplastics), almost all thermoplastic materials can be produced using injection molding methods. Injection molding is not only used for the molding of thermoplastic materials, but has also been successfully applied to the molding of thermosetting plastics.

At present, its molded products account for 20-30% of all plastic products. In order to further expand the scope of injection molded plastic parts, some specialized injection technologies have been developed for molding plastic parts with special performance or structural requirements, such as precision injection of high-precision plastic parts, multi-color injection of composite color plastic parts, sandwich injection of sandwich plastic parts composed of different materials inside and outside, and injection compression molding of optical transparent plastic parts.

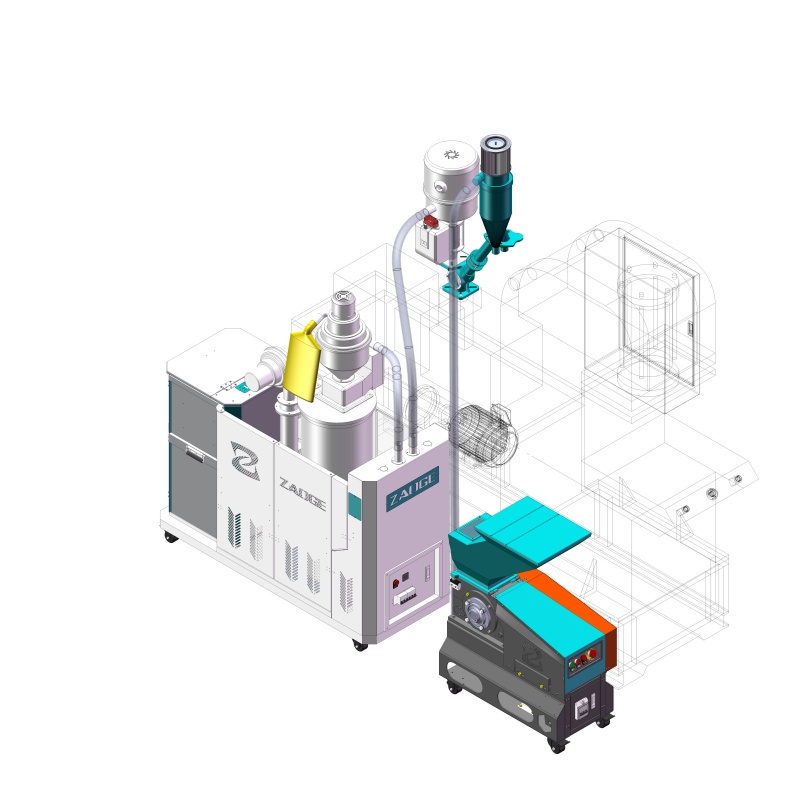

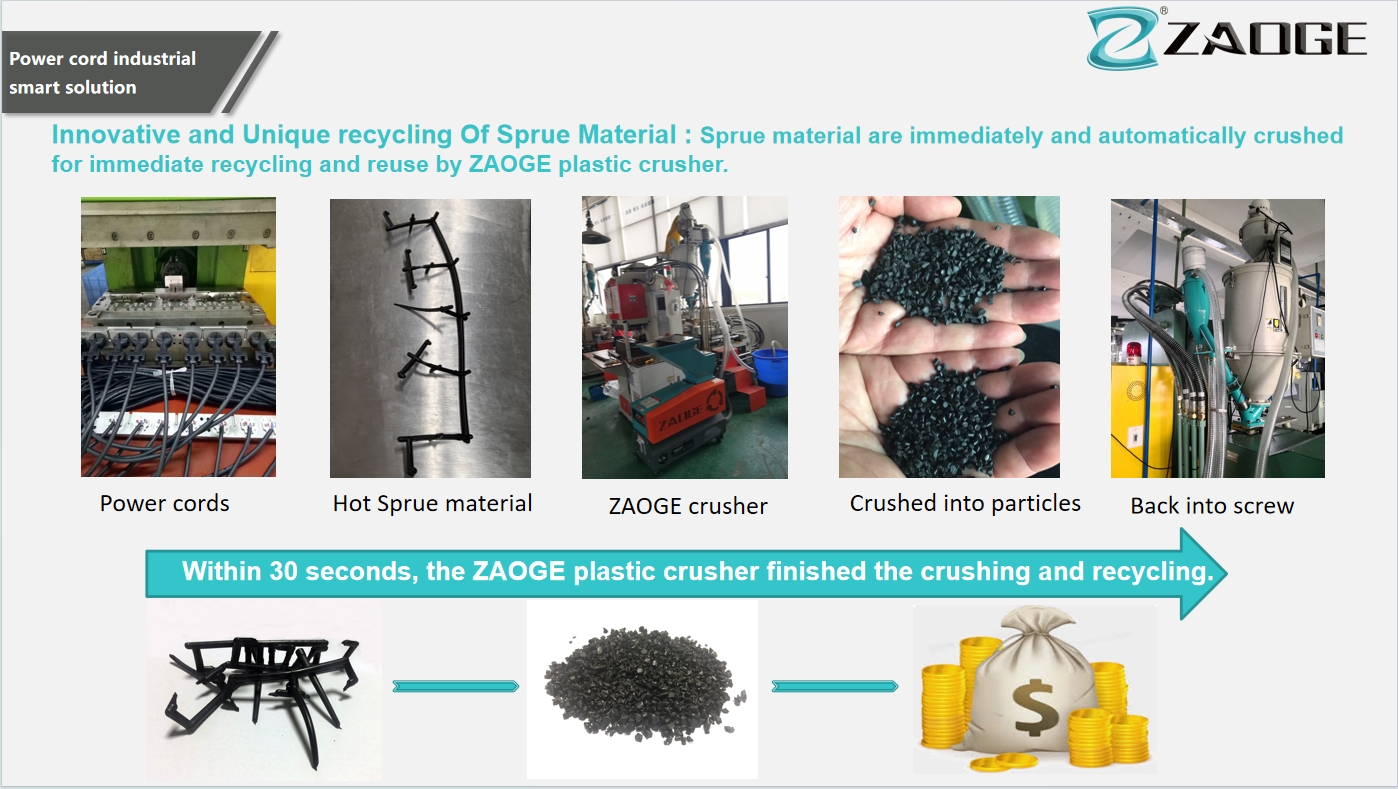

ZAOGE Automated Thermal Crushing Environmental Protection Utilization Solution Special for soft plastic

ZAOGE PLASTIC CRUSHER suitable for the fields of data cables, plug cables, cable cables, new energy, and flexible product molding (such as PVC, PP, PE, TPE, TPU, and other soft inner plastic.

Post time: May-13-2024