Plastic injection molding

(1) Plastic injection molding

Injection molding: also known as injection molding, its principle is to heat and melt plastic particles, inject the melted plastic into the mold through an injection machine, cool and solidify under a certain pressure and temperature, and finally form the required plastic products.

(2) Process characteristics

The advantages of injection molding include high production efficiency, relatively low cost, the ability to produce complex parts and products, a wide range of material choices, and the ability to automate production. The disadvantages include high equipment investment, high initial costs, and high requirements for mold and equipment accuracy.

(3) Application area

Injection molding is widely used in fields such as automotive parts, household appliances, daily necessities, medical equipment, toys, etc. Its efficient production methods and diverse product forms have made injection molding technology the mainstream production method in the plastic product industry.

Insert injection molding

(1) Insert injection molding

It is the process of embedding non plastic materials such as metals and plastics into plastic products during injection molding. Through mold design, the insert is fixed in a designated position during the injection molding process, ensuring a tight connection between the insert and the plastic product, achieving functional or decorative requirements.

(2) Process characteristics

It can achieve integrated assembly of plastic products and other materials, improving the overall performance of the product.

Save subsequent assembly processes, reduce production costs and labor costs.

It can achieve the combination of complex structures to meet the requirements of product functionality and appearance design.

Precision mold design and high-precision injection molding equipment are required, with high process requirements.

Two color injection molding

(1) Two color injection molding

It is a molding process that uses an injection molding machine to inject two kinds of plastics of different colors or materials into the same mold in turn. Through the mold structure, the two kinds of plastics can be perfectly combined, so as to achieve the manufacturing of plastic products with colorful appearance.

picture

(2) Process characteristics

Diversify product appearance, increase product aesthetics and decoration.

Reduce subsequent painting or assembly processes to improve production efficiency.

Specially designed dual color injection molds are required, resulting in high investment costs.

Suitable for products that require colorful effects, such as automotive parts, household items, etc.

Micro foaming injection molding process

(1) Microfoam injection molding

It is the process of injecting gas or foaming agent into plastic during injection molding, causing the plastic to produce small bubble structures during the molding process, thereby reducing density, reducing weight, and increasing insulation performance. This process can be applied in lightweight design and energy-saving and environmental protection fields.

(2) Process characteristics

Reduce product density, reduce weight, and save raw material costs.

Improve the insulation performance and sound absorption effect of the product.

Improve product surface quality, reduce warping and deformation.

(3) Application area

Microfoam injection molding is widely used in automotive components, packaging materials, electronic product casings, and other fields, especially suitable for application scenarios with high requirements for product weight, cost, and performance.

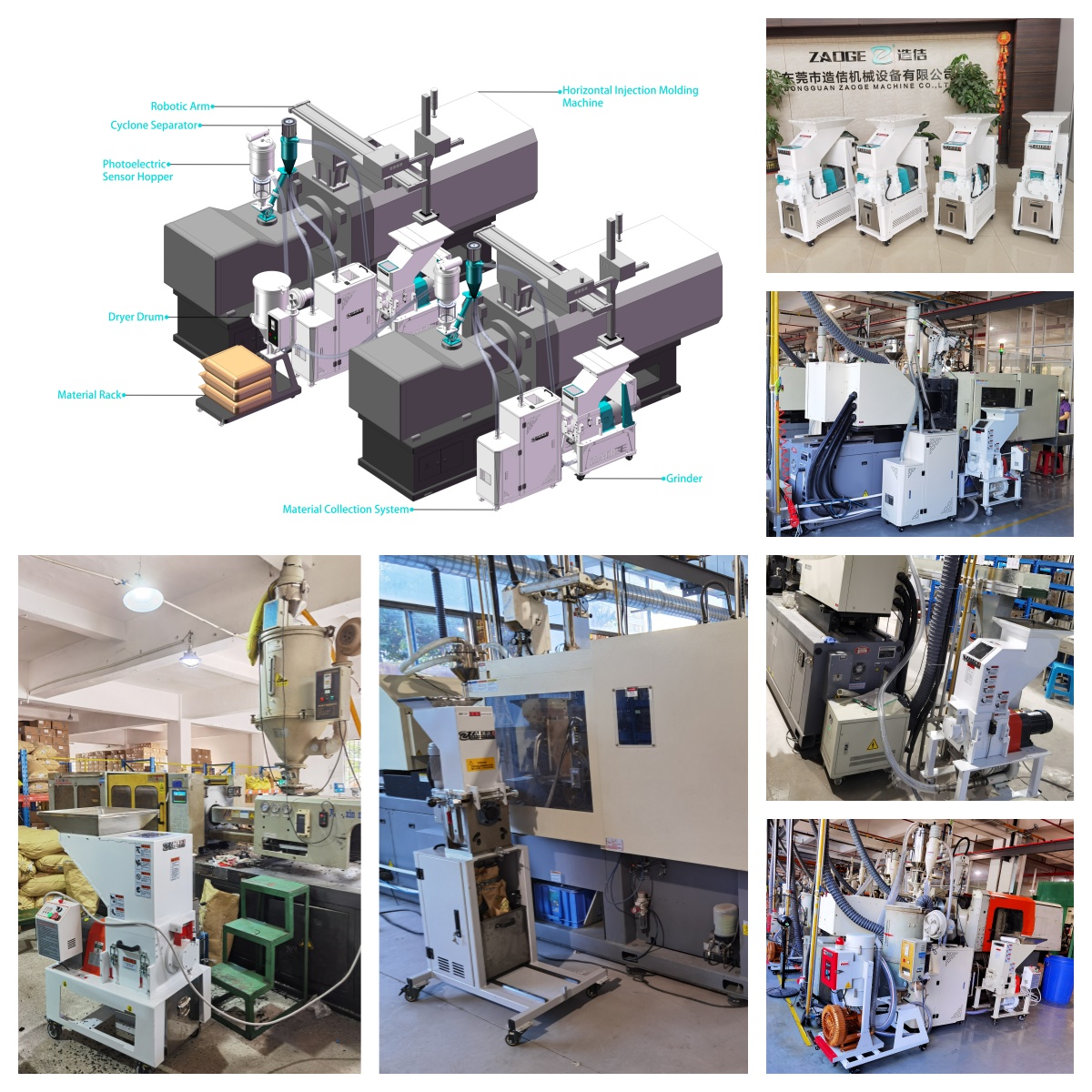

Regardless of the type of injection molding, it will produce sprue and runner materials. By using the ZAOGE environmentally friendly and energy-saving crusher, the sprue and runner materials are immediately crushed and recycled, achieving the reshaping and value recovery of waste, achieving the goals of environmental protection and resource utilization, and is the most scientific and innovative way to increase profits.

Post time: May-15-2024